Rotary Gear Pumps (DW)

Product Details:

- Working Temperature Up to 80C

- Max Suction 7 meters (Approximate)

- Mounting Type Base Plate Mounted

- Frequency 50 Hz

- Speed 1440 RPM

- Discharge Pressure Up to 10 Bar

- Features Sturdy Construction, High Efficiency, Long Service Life

- Click to View more

Rotary Gear Pumps (DW) Price And Quantity

- 2000.00 - 18000.00 INR/Piece

- 1-100 Piece

Rotary Gear Pumps (DW) Product Specifications

- Self-Priming

- Up to 30 m/hr

- Oil, Diesel, Edible Oil, Viscous Liquids

- 12.5 mm to 100 mm

- Not Applicable (Electric Driven)

- Up to 100 meters

- Transfer of Oil, Viscous Liquids

- 220-415 V

- N/A (Electric Driven)

- Rotary Positive Displacement

- Mechanical Seal

- Low Noise Operation

- 1/2 to 4 BSP (Threaded / Flanged)

- Up to 500 LPM

- Electric Watt (w)

- As per IS / Custom Design

- Gear Pump

- Sturdy Construction, High Efficiency, Long Service Life

- GI

- 1440 RPM

- 50 Hz

- Positive Suction

- Up to 10 kg/cm

- Up to 10 Bar

- Base Plate Mounted

- Rotary Gear Pump (DW)

- 7 meters (Approximate)

- Up to 80C

Rotary Gear Pumps (DW) Trade Information

- 1 Piece Per Day

- 2 Days

- Australia, South America, Western Europe, Middle East, Central America, Asia, Eastern Europe, North America, Africa

Product Description

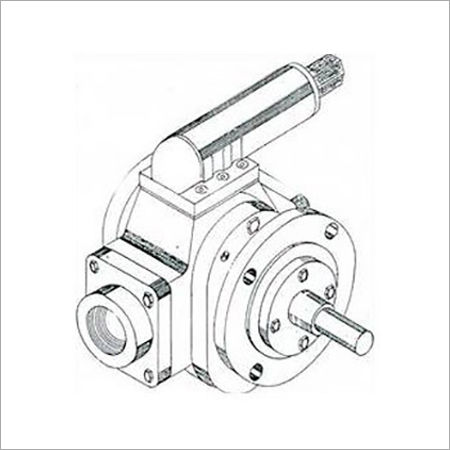

A Rotary Gear Pumps (DW) are a type of positive displacement pump. This moves the fluid on a repetition inside an enclosed fixed volume with the use of interlocking gears and cogs. This transfers it mechanically with the use of cyclic pumping actions. This also helps deliver a smooth plus-free flow proportional to the rotational speed of the gears. Rotary Gear Pumps (DW) are positive displacement pumps. The pump generates its flow by the employment of idler gear assembly or simply rotors.

Specification

| Model | Inlet Outlet Size | Rated Capacity At 1440 Rpm Lpm M3/Hr | Weight In Kg | |

| DW-1-025 | 1/4" x 1/4" | 05 | 0.30 | 7 |

| DW-1-040 | 3/8"x3/8" | 10 | 0.60 | 7 |

| DW-1-050 | 1/2" x 1/2" | 15 | 0.90 | 9 |

| DW-1-075 | 3/4" x 3/4" | 25 | 1.50 | 9 |

| DW-1-075SP | 3/4" x 3/4" | 35 | 2.10 | 9 |

| DW-1-100 | 1"x1" | 50 | 3.00 | 15 |

| DW-1-125 | 1 1/4"x1 1/4" | 75 | 4.50 | 15 |

| DW-1-125SP | 1 1/4"x1 1/4" | 100 | 6.00 | 15 |

| DW-1-150 | 1 1/2"x1 1/2" | 125 | 7.50 | 27 |

| DW-1-150SP | 1 1/2"x1 1/2" | 150 | 9.00 | 27 |

| DW-1-200 | 2"x2" | 200 | 12.00 | 27 |

| DW-1-200SP | 2"x2" | 225 | 13.50 | 27 |

| MODEL | A | B | C | D | *D | *D1 | E | F | G | H | I | J | K | L1 | L2 | M | N | S | PQBSP |

| DW-1-025, 040 | 183 | 75 | 35 | 25 | 12 | 9 | 12 | 3 | 55 | 110 | - | 84 | 101 | 53.5 | 68.5 | 12 | 4 | 4 | 1/4"X3/"BSP |

| DW-1-050, 075, 075(SP) | 205 | 95 | 42 | 35 | 18 | 9 | 20 | 5 | 75 | 150 | 45 | 114 | 97.5 | 68 | 86 | 15 | 6 | 6 | 1/2"X3/4"BSP |

| DW-1-100, 125, 125(SP) | 243 | 116 | 52 | 45 | 20 | 11 | 20 | 5 | 86 | 190 | 50 | 140 | 110 | 88 | 115 | 17 | 6 | 6 | 3/4"X1/4"BSP |

| DW-1-150,150(SP),200,200(SP) | 280 | 134 | 60 | 55 | 28 | 11 | 20 | 5 | 105 | 200 | 65 | 160 | 127 | 106 | 139 | 22 | 8 | 8 | 1/2"x1/2"BSP |

Reliable and High-Performance Pumping

Rotary Gear Pumps (DW) utilize a powerful rotary positive displacement mechanism, ensuring consistent flow of viscous and non-viscous fluids. With operation up to 500 LPM, a 10-bar pressure limit, and compatibility with a wide range of fluidsincluding mineral oil and edible oilsthese pumps are ideal for diverse industrial sectors in need of robust, energy-efficient solutions.

Durable Build and Long Service Life

Built from sturdy GI materials with dual gear design, these pumps are engineered for longevity. Anti-friction ball bearings and self-lubricating gears minimize wear, while a corrosion-resistant coating enhances durability. Easy to dismantle and reassemble, they facilitate hassle-free maintenance, boosting productivity and reducing downtime.

Customizable and Versatile Applications

Standard models rotate clockwise, but options to customize for unique operational needs are available. Rotary Gear Pumps (DW) support various inlet/outlet sizes and can be adapted to specific industrial requirements. Applications span oil, diesel, edible oil, and other viscous liquids, ensuring flexibility across multiple industries such as manufacturing, chemical processing, and energy.

FAQs of Rotary Gear Pumps (DW):

Q: How do I maintain a Rotary Gear Pump (DW) for optimal performance?

A: Maintenance is straightforward due to its design. The pumps are easy to dismantle and reassemble, allowing for regular inspections and cleaning. Self-lubricating gears and anti-friction bearings reduce maintenance needs, but routine checks for seal integrity and corrosion protection are recommended.Q: What fluids are Rotary Gear Pumps (DW) suitable for?

A: These pumps are designed to handle a wide range of fluids, including mineral oil, crude oil, viscous chemicals, edible oils, diesel, and other viscous liquids with a viscosity of up to 1,00,000 cst.Q: When is it necessary to customize a Rotary Gear Pump (DW)?

A: Customization is beneficial when the standard clockwise rotation, capacity, size, or material does not fit your specific application. Custom designs can accommodate unique operational requirements or industry standards.Q: Where can Rotary Gear Pumps (DW) be installed?

A: They are typically base plate mounted and suitable for industrial settings such as chemical plants, oil processing units, and manufacturing facilities. Their corrosion-resistant coating makes them adaptable for challenging environments.Q: What is the process for priming this pump, and why is it beneficial?

A: The Rotary Gear Pump (DW) features a self-priming mechanism, which automatically removes air from the system, allowing for immediate and efficient operation. This reduces manual intervention and startup delays.Q: How does the design improve the efficiency and lifespan of the pump?

A: Dual gears, self-lubricating components, and anti-friction ball bearings minimize internal friction, leading to higher efficiency, low noise levels, and extended service life. The corrosion-resistant coating further enhances longevity.Q: What are the main benefits of using Rotary Gear Pumps (DW) in industrial applications?

A: Key benefits include high efficiency, low noise operation, sturdy construction, long service life, easy maintenance, and adaptability to various viscous fluids. The pumps meet standard IS or custom designs, offering tailored solutions for diverse industries.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+