Welcome to our company

Rotary Gear Pumps (DIBX)

2000.00 - 18000.00 INR/Piece

Product Details:

- Inlet/Outlet 1/4 to 3 BSP (Female)

- Voltage 220-440 V

- Theory Rotary Gear

- Noise Level < 70 dB

- Flow Rate 10 LPM to 500 LPM

- Speed 1440 RPM

- Frequency 50 Hz

- Click to View more

X

Rotary Gear Pumps (DIBX) Price And Quantity

- 2000.00 - 18000.00 INR/Piece

- 1-100 Piece

- Hardened steel

- Blue / Grey (Standard)

- Continuous

- Self-lubricating gears

- Flexible / Rigid coupling options available

- Clockwise (CW) / Anti-clockwise (ACW)

- 10 to 60,000 cst

- Special models available for up to 200°C

- 0.05% (non-abrasive)

- Varies by model (approx. 12 kg to 180 kg)

- Alloy steel

- Threaded / Flanged as per model

- PTFE / Nitrile / Viton (as per fluid compatibility)

- Cast Iron with anti-corrosive paint

Rotary Gear Pumps (DIBX) Product Specifications

- Upto 10 kg/cm

- Upto 80C

- Oil Transfer, Diesel, Kerosene, Hydraulic Oils

- IS 11793 (Part I), API Std.

- GI

- Base Mounted / Foot Mounted

- Self-priming

- 5 Meter (Wet)

- As per model (standard bore sizes)

- Manual / Auto (as per configuration)

- Electric Watt (w)

- N/A (not integrated)

- Upto 100 Meter

- Rotary Gear Pump (DIBX)

- Positive Displacement

- 50 Hz

- Upto 10 kg/cm

- Mechanical Seal

- 0.2 m/hr to 30 m/hr

- Gear Pump

- Diesel, Oil

- 1440 RPM

- 10 LPM to 500 LPM

- 220-440 V

- Rotary Gear

- < 70 dB

- Chemical Process, Oil Transfer, Food Industry, Pharmaceuticals

- 1/4 to 3 BSP (Female)

- Hardened steel

- Blue / Grey (Standard)

- Continuous

- Self-lubricating gears

- Flexible / Rigid coupling options available

- Clockwise (CW) / Anti-clockwise (ACW)

- 10 to 60,000 cst

- Special models available for up to 200°C

- 0.05% (non-abrasive)

- Varies by model (approx. 12 kg to 180 kg)

- Alloy steel

- Threaded / Flanged as per model

- PTFE / Nitrile / Viton (as per fluid compatibility)

- Cast Iron with anti-corrosive paint

Rotary Gear Pumps (DIBX) Trade Information

- 1 Piece Per Day

- 2 Days

- Asia, Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Central America, Africa

Product Description

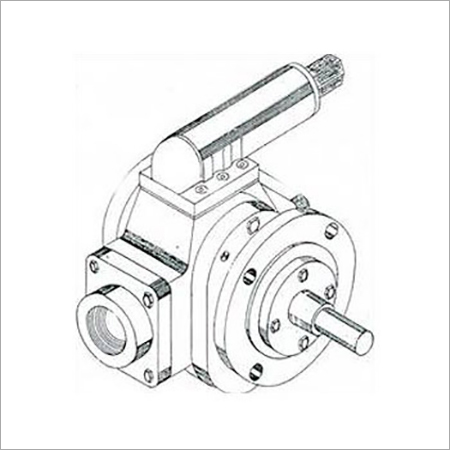

Rotary Gear Pumps (DIBX) are positive displacement pumps which depend on rotational motion rather than reciprocating motion during the pumps operational cycle. They can be designed to pump solids, liquids, gases or a mixture of the three. They are extensively used for loading-unloading and transferring of all types of petroleum products and viscous liquids. Rotary Gear Pumps (DIBX) move the fluid on a repetition inside an enclosed fixed volume with the use of interlocking gears and cogs. This transfers it mechanically with the use of cyclic pumping actions.Key Features and Construction

The DIBX Rotary Gear Pump boasts a sturdy cast iron casing with anti-corrosive paint, a hardened steel rotor, and an alloy steel shaft for superior durability. Threaded or flanged connections are available depending on the model, while gears are self-lubricating for minimal maintenance. Precision mechanical seals and flexible/ridged couplings ensure safe and leak-free operation, making this pump suitable for continuous duty cycles.

Versatile Applications and Usage

This pump is tailored for demanding environments such as chemical processing, oil transfer, the food industry, and pharmaceuticals. Its wide viscosity support and high temperature capability allow for the transfer of various fluids including diesel, hydraulic oils, and light chemicals. The DIBX model handles up to 0.05%% non-abrasive solid content, providing solutions for processes requiring reliable and consistent pumping under varying conditions.

Performance and Control Advantages

Engineered for self-priming action and positive displacement, the DIBX Rotary Gear Pump can generate flow rates from 10 to 500 LPM and head sizes up to 100 meters. Operating with a noise level below 70 dB and supporting both manual and automatic control systems, users gain energy efficiency, operational safety, and adaptability for continuous industrial operations. The flexible base or foot mounting options allow for easy integration into existing setups.

FAQs of Rotary Gear Pumps (DIBX):

Q: How does the DIBX Rotary Gear Pump handle varying fluid viscosities?

A: The DIBX Rotary Gear Pump is designed to efficiently handle fluids with viscosities ranging from 10 to 60,000 cst. Its robust construction and self-lubricating gears ensure stable performance across this broad range, making it suitable for diverse applications such as oil, diesel, and certain chemicals.Q: What are the typical usage scenarios for the DIBX Rotary Gear Pump?

A: Typical applications include oil transfer, diesel and kerosene pumping, hydraulic fluid management, and chemical processing. The pumps excellent temperature resistance and solid handling capabilities also make it ideal for use in food industry and pharmaceutical processes.Q: When should I select threaded versus flanged connections for this pump?

A: Threaded connections are often chosen for lower-capacity or smaller installations, while flanged connections are preferable for higher flow rates and industrial applications requiring stronger, more secure piping systems. The choice depends on the model selected and the installation environment.Q: Where can the DIBX Rotary Gear Pump be mounted for optimal performance?

A: The pump is designed for flexible installation, allowing for either base-mounted or foot-mounted configurations. This ensures it can be integrated effectively into various industrial setups, ideal for both stationary plant room and mobile transfer systems.Q: What is the process for selecting the correct seal material?

A: The appropriate seal (PTFE, Nitrile, or Viton) should be selected based on the chemical compatibility with the fluid being pumped. For example, Viton is ideal for aggressive chemicals, while Nitrile is suitable for petroleum-based fluids. Consult the supplier for precise recommendations based on your application.Q: How does self-priming benefit daily operations?

A: With its self-priming capability, the DIBX Rotary Gear Pump can start pumping without requiring manual priming. This reduces setup time and simplifies regular usage, promoting easier and more efficient operation particularly in processes with frequent start-stop cycles.Q: What are the key benefits of choosing this pump for industrial use?

A: Users benefit from durable construction, continuous duty cycle capability, precise flow control, and low maintenance requirements. Additionally, the pump operates quietly (<70 dB), supports flexible control options, and meets established quality standards, providing reliable long-term service in critical industrial applications.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free