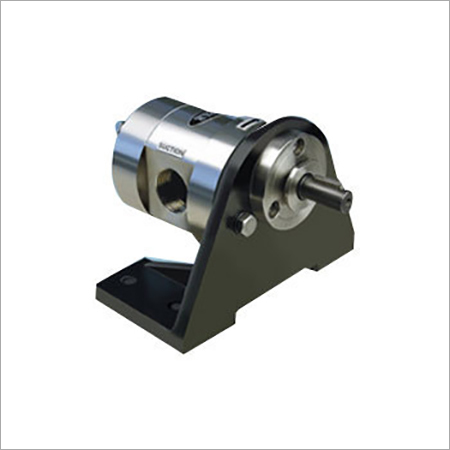

Rotary Gear Pumps (CGSS)

Product Details:

- Discharge Pressure Upto 10 bar

- Working Temperature Upto 200C

- Inlet/Outlet 1/4 to 3 BSP (Threaded)

- Max Suction 5 Meter

- Noise Level Low

- Flow Rate 10 LPM to 500 LPM

- Head Size 10 to 100 Meter

- Click to View more

Rotary Gear Pumps (CGSS) Price And Quantity

- 1-100 Piece

- 2000.00 - 18000.00 INR/Piece

Rotary Gear Pumps (CGSS) Product Specifications

- 0.25 m/hr to 30 m/hr

- Upto 10 kg/cm (10 bar)

- 10 LPM to 500 LPM

- 10 to 100 Meter

- Self-Priming

- ISO Certified

- Electric Watt (w)

- Positive Suction

- Transfer of Oils, Viscous Liquids, Chemicals

- GI

- 1/4 to 3 BSP (Threaded)

- Upto 200C

- Upto 10 bar

- Low

- 5 Meter

- 220-415 V

- Gear Pump

- Oil Transfer, Chemical, Viscous Liquid Handling

- 1440 RPM

- Rotary Gear Displacement

- Standard

- Rotary Gear Pump (CGSS)

- 50 Hz

- Mechanical Seal

- Foot Mounted

Rotary Gear Pumps (CGSS) Trade Information

- 1 Piece Per Day

- 2 Days

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America, Asia

Product Description

The Rotary Gear Pumps (CGSS) is self priming bi directional positive displacement pumps in all ss-316 construction, case nitided shafts and gear supported on eight side of 4, nos. Teflon coated self lubricated dry bush bearings. Rotary pumps are positive displacement pumps which depend on rotational motion rather than reciprocating motion during the pumps operational cycle. These pumps have close tolerances between the rotors and the walls of the pump. Rotary Gear Pumps (CGSS) is very useful and made for industrial use.

Power Chart

Model | Port Size BSP | Capacity At 1400 Rpm | Approx Wt.In Kg. | ||

M3/hr | LPM | US GPM | |||

CG-025 | 1/4" x 1/4" | 1.30 | 5.00 | 0.30 | 1.80 |

2.20 | 8.33 | 0.50 | 2.00 | ||

CG-040 | 3/8" X 3/8" | 4.40 | 16.66 | 1.00 | 3.00 |

CG-050 | 1/2" X 1/2" | 6.60 | 25.00 | 1.50 | 3.50 |

CG-075 | 3/4" x 3/4" | 8.80 | 33.33 | 2.00 | 4.50 |

CG-100 | 1" x 1" | 13.20 | 50.00 | 3.00 | 5.00 |

CG-125 | 1 1/4" x 1 1/4" | 26.40 | 100 | 6.00 | 6.00 |

CG-150 | 1 1/2" x 1 1/2" | 33.00 | 125 | 7.50 | 10.500 |

CG-200 | 2" X 2" | 39.60 | 150 | 9.00 | 20.500 |

52.80 | 200 | 12.00 | 24.00 | ||

Dimension

| SIZE | A | B1 | C | C1 | D1 | E | E1 | E2 | F | G | H | H1 | H2 | L1 | L2 | P | Q | PQ.B.S.P |

| 025 | 128 | 25 | 17 | 3 | 11.5 | 8 | 40 | 120 | 72 | 54 | 12 | 63 | 50.5 | 101 | 94 | 35 | 3 | 1/4"x1/4" |

| 040 | 134 | 25 | 17 | 3 | 11.5 | 8 | 50 | 125 | 75 | 61 | 14 | 80 | 66 | 121 | 98.5 | 35.5 | 4 | 3/8"x3/8" |

| 050 | 146 | 25 | 17 | 3 | 11.5 | 8 | 50 | 125 | 77 | 72.5 | 14 | 80 | 66 | 121 | 104 | 42 | 4 | 1/2"x1/2" |

| 075 | 169 | 35 | 25 | 3 | 14 | 10.5 | 53.5 | 140 | 82.5 | 72.5 | 17 | 100 | 83 | 143 | 123 | 46 | 5 | 3/4"x2/4" |

| 100 | 179 | 35 | 25 | 3 | 14 | 10.5 | 53.5 | 140 | 92.5 | 90 | 17 | 100 | 83 | 143 | 128 | 51 | 51 | 1"x1" |

| 125 | 212 | 38 | 30 | 3 | 18 | 12 | 50 | 110 | 98.5 | 90 | 21 | 112 | 91 | 161 | 146 | 66 | 6 | 1/4"x1/4" |

| 150 | 229 | 38 | 30 | 3 | 18 | 12 | 50 | 132 | 101 | 103 | 21 | 112 | 91 | 161 | 156 | 73 | 6 | 1/3"x1/3" |

| 200 | 259 | 40 | 30 | 5 | 24 | 14 | 75 | 145 | 107 | 103 | 25 | 132 | 107 | 132 | 174 | 85 | 8 | 2"x2" |

| 200 | 283 | 40 | 30 | 5 | 24 | 14 | 75 | 160 | 107 | 103 | 25 | 132 | 107 | 187 | 186 | 97 | 8 | 2"x2" |

Superior Construction and Reliability

Featuring a robust cast iron body with stainless steel shafts and double helical gears, the CGSS Rotary Gear Pump guarantees durability and precision. The powder-coated or painted surface finish enhances corrosion resistance, allowing this pump to withstand challenging industrial conditions and provide long-term, reliable operation.

Effortless Integration and Customization

The pump supports port sizes ranging from 1/4 to 3 BSP threaded inlets/outlets and delivers flexible direction of rotationclockwise as standard, with anticlockwise available on request. Its mechanical seal, self-lubricating design, and compact foot-mounted structure facilitate straightforward installation and efficient performance in diverse environments.

Performance Across a Broad Range of Applications

Suitable for oil transfer, chemical handling, and viscous liquid transport, the CGSS Rotary Gear Pump achieves high discharge pressures up to 10 bar and heads from 10 to 100 meters. Self-priming capability and low-noise operation further enhance its suitability for continuous industrial and commercial processes.

FAQs of Rotary Gear Pumps (CGSS):

Q: How does the CGSS Rotary Gear Pump ensure reliable operation in industrial environments?

A: This pump features a cast iron body, stainless steel shafts, and double helical gears that deliver durability and resistance to wear. Its powder-coated or painted finish protects against corrosion, while mechanical seals prevent leaks, making it ideal for demanding industrial settings.Q: What types of liquids can be transferred using the CGSS Rotary Gear Pump?

A: The CGSS is suitable for pumping oils, viscous liquids, and chemicals with viscosities up to 100,000 SSU (21,825 cSt). Its robust design easily handles fluids commonly found in chemical plants, oil transferring stations, and various commercial environments.Q: Where is the CGSS Rotary Gear Pump typically installed?

A: It is commonly used in industrial facilities, chemical processing plants, and commercial sites that require efficient transfer of oils or viscous fluids. The foot-mounted structure supports versatile installation on stable surfaces.Q: When is it necessary to request an anticlockwise direction of rotation for the pump?

A: Anticlockwise rotation should be specified when system design or piping configurations require the pump to operate in the opposite direction from the standard clockwise orientation. This can be arranged at the time of order to suit specific operational requirements.Q: What benefits does the self-lubricating design offer for maintenance?

A: The rotary self-lubricated mechanism significantly reduces the need for external maintenance and manual lubrication, resulting in lower downtime and enhanced operational efficiency.Q: How does the self-priming capability improve the pumps usage?

A: The self-priming feature enables the pump to efficiently initiate fluid transfer without manual intervention, particularly beneficial for handling viscous liquids and ensuring uninterrupted process flows.Q: What is the minimum order quantity for the Rotary Gear Pump (CGSS)?

A: The minimum order quantity for the CGSS Rotary Gear Pump is one piece, allowing for immediate procurement whether for replacement, upgrade, or new installations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+