Welcome to our company

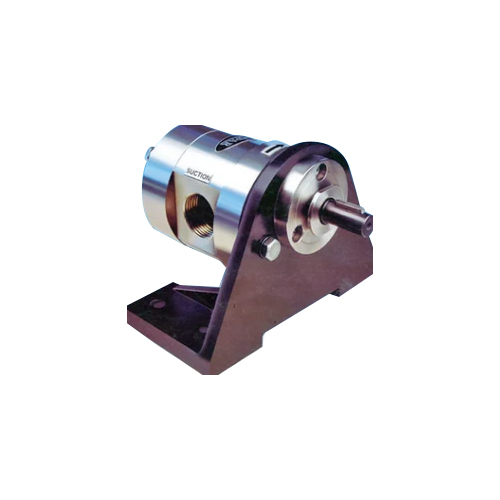

Rotary Gear Pump

Product Details:

- Max Suction 5 meters

- Voltage 220V

- Inlet/Outlet 1 x 1 BSP (British Standard Pipe)

- Theory Rotary Gear Pump

- Speed 1440 RPM

- Working Temperature Up to 80C

- Mounting Type Foot Mounted

- Click to View more

X

Rotary Gear Pump Price And Quantity

- 1 Unit

Rotary Gear Pump Product Specifications

- 10 LPM (Liters Per Minute)

- 0.5 HP

- Low Noise (< 70 dB)

- Lubrication, Oil Transfer, Fuel Handling

- Manual On/Off

- Gear Pump

- Gear Pump

- 25 mm

- Self Priming

- Up to 600 LPH

- 50 Hz

- Close Coupled Horizontal

- 5 meters

- Industrial Oil Transfer

- Positive Displacement

- 220V

- Diesel, Oil, Light Viscous Liquids

- High Pressure

- IS Standard Compliant

- 1 x 1 BSP (British Standard Pipe)

- Rotary Gear Pump

- 1440 RPM

- Gear Pump

- Up to 80C

- Foot Mounted

- Mechanical Seal

- Up to 5 kg/cm

- Up to 50 meters

Rotary Gear Pump Trade Information

- 7-10 Days

Product Description

The premium quality Rotary Gear Pumps that we offer is extensively used for loading-unloading and transferring of all types of petroleum products and viscous liquids. We make this range of Rotary Gear Pumps from premium raw materials.

This range is valued for such unique features such as availability in different sizes

1/2" to 6"NB size flanged to ASA-150. It has B.16.5 class capacity that varies from 0.5 to 200 M/hr. The pressure is up to 11kg/cm . The viscosity range is up to 1, 00,000 CST The temperature variation can go up to 110 degree celsius

It is available up to 250 degrees celsius

Precision Engineering for Industrial Reliability

Built with versatility in mind, our rotary gear pumps offer sturdy construction, with alloy steel shafts, flexible coupling, and a choice of Cast Iron or Stainless Steel for optimal durability. The inline port orientation and compact, foot-mounted design ensure easy installation in diverse industrial settings. Designed for consistent use, it serves lubrication, oil transfer, and fuel handling tasks with efficiency and reliability.

Superior Performance and Safety Features

Delivering high pressure and self-priming action, these pumps handle fluids at temperatures up to 80C and ambient conditions up to 45C. The noise level is kept under 70 dB, ensuring a quieter workspace. The mechanical seals and quality surface finisheither painted or polishedare selected for enhanced protection and longevity, meeting stringent IS standards.

Beneficial Solutions for Industrial Applications

Our rotary gear pump ensures efficient fluid transmission for industries requiring precise handling of light viscous or non-corrosive liquids. With easy manual controls, flexible mounting, and options for voltage, port size, and surface finish, the pump adapts to specific user needs. The quick availability of replacement parts and tailor-able features provide lasting value and peace of mind.

FAQs of Rotary Gear Pump:

Q: How is the rotary gear pump installed and where can it be used?

A: The pump is foot-mounted and designed for horizontal, close-coupled installation, fitting well in diverse industrial setups like lubrication systems, oil transfer units, and fuel handling stations. Its inline port orientation and compact build allow versatile placement.Q: What types of liquids can this gear pump handle effectively?

A: This rotary gear pump is engineered for non-corrosive, light viscous liquids such as diesel, oil, and other similar industrial fluids with viscosities up to 1,000 cst. It is not recommended for corrosive or abrasive substances.Q: When should the pumps mechanical seals or replacement parts be serviced or replaced?

A: Regular maintenance checks are advised based on operating hours and liquid characteristics. If you notice leakage, reduced flow, or noise, inspect and replace mechanical seals (Nitrile Rubber or Viton) and other worn parts. Replacement components are readily available from the manufacturer or supplier.Q: How does the pump ensure efficient and safe operation?

A: The gear pump uses a positive displacement design with a self-priming feature, flexible coupling, and robust mechanical seals. Its construction supports handling up to 80C liquid temperature and 45C ambient temperature, ensuring both efficiency and operator safety.Q: What are the benefits of using this rotary gear pump in industrial applications?

A: The pump offers high-pressure, low-noise (<70 dB) operation, reliable flow rates, IS standard compliance, and customization options for color and surface finish. Its durable build and ease of servicing translate to reduced downtime and productivity gains.Q: Can the port orientation or color be customized for specific installation requirements?

A: Yes, port orientation is inline by default, but consultation with the supplier may accommodate unique installation needs. Color can be customized upon request to match site-specific or branding requirements.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email